Published Saturday June 28, 2014: Updated June 27, 2015

The temperature in our attic exceeds 145°F during the summer time. That’s a lot of heat energy that could and should be used for something useful, if only we could find a way to effectively harness and use it.

I have been thinking about ways to use that free heat to dry clothes. While a clothes rack or clothes line is super energy efficient and provides additional benefits, (whiter whites, less wrinkles and less wear and tear on the clothes themselves), it is still kind of inconvenient if you have a lot of laundry to do, or need to dry clothes quickly, or when the weather is not conducive to drying clothes outside.

While clothes dryers are convenient and will dry clothes very quickly, regardless of the weather outside, they still use a tremendous amount of energy. They also deplete the house of air that may have already been air conditioned. A typical clothes dryer drafts air from inside the house at the rate of 150 cubic feet per minute. Then it exerts a huge amount of heat energy on it, heating it up. As the hot air passes through, some of the moisture from the damp clothes is transferred to the super-heated air and the dryer blows the hot, moist air outside.

A 33 minute dryer cycle will pull 5000 cubic feet of air from inside the house. If you did 4 loads in the clothes dryer, it would transfer the entire volume of air for a 2500 sq-ft house. Replacement air would then be drawn in to the house and that air would then need to be either heated or cooled by the home's HVAC system.

It's Crazy Hot in the Attic so why not use some of that free heat to feed the clothes dryer, offsetting its energy consumption?

This serves a 3-fold purpose:

- Reduce the energy spent drying clothes by more than 1/2.

- Cool down attic (reducing HVAC energy usage), as well as extending the life of the roof.

- Reduce air draft/leakage inside the home, saving HVAC energy costs.

Trying It Out

As luck would have it, the newly acquired electric clothes dryer (that I procured for this experiment) has a couple, large, 4” knock-out holes on the left and right sides. It took all of 2 minutes to knock out a single, perfectly smooth round hole on one side.

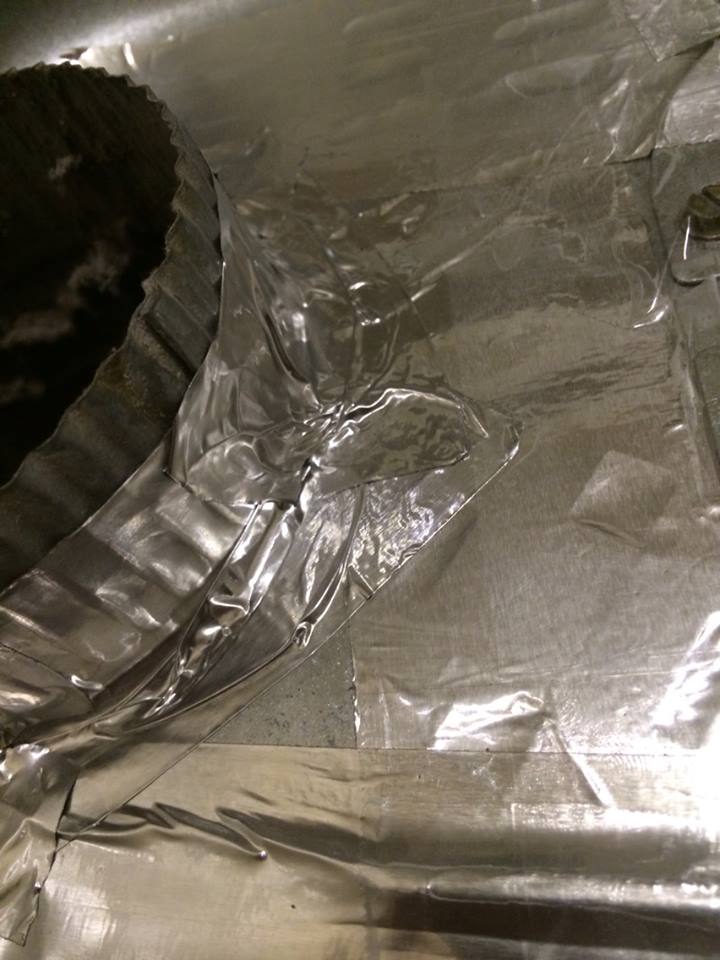

So the blower motor could better draft in its own air from the attic, I sealed off all the seams and vent holes in the clothes dryer (except for the exhaust hole).

I used metal tape for the back and clear-tape on the sides.

Even a small open ring around the exhaust duct would draft in air if it weren't sealed off.

Even small gaps under the knobs suck in air and had to be sealed off.

Using a lit incense stick for a smoke test, I was able to locate additional pin-hole air leaks and seal them off.

Surprisingly the dryer door had a very good, air-seal. Once the dryer is sealed air tight so that only the (newly added) intake duct can allow air to enter, the blower motor is able to draft attic air all by itself. If you completely block off the intake duct, the dryer reacts violently as if it's going to implode. "Now that's a good draft/blower motor".

I ran an air duct from the top of the attic down into the house. In this manner, the air pulled from the attic is always the hottest and will not disturb the insulation in the attic. Undisturbed attic air is surprisingly clean and no input air filtration is necessary.

Air duct running from the attic into the laundry room.

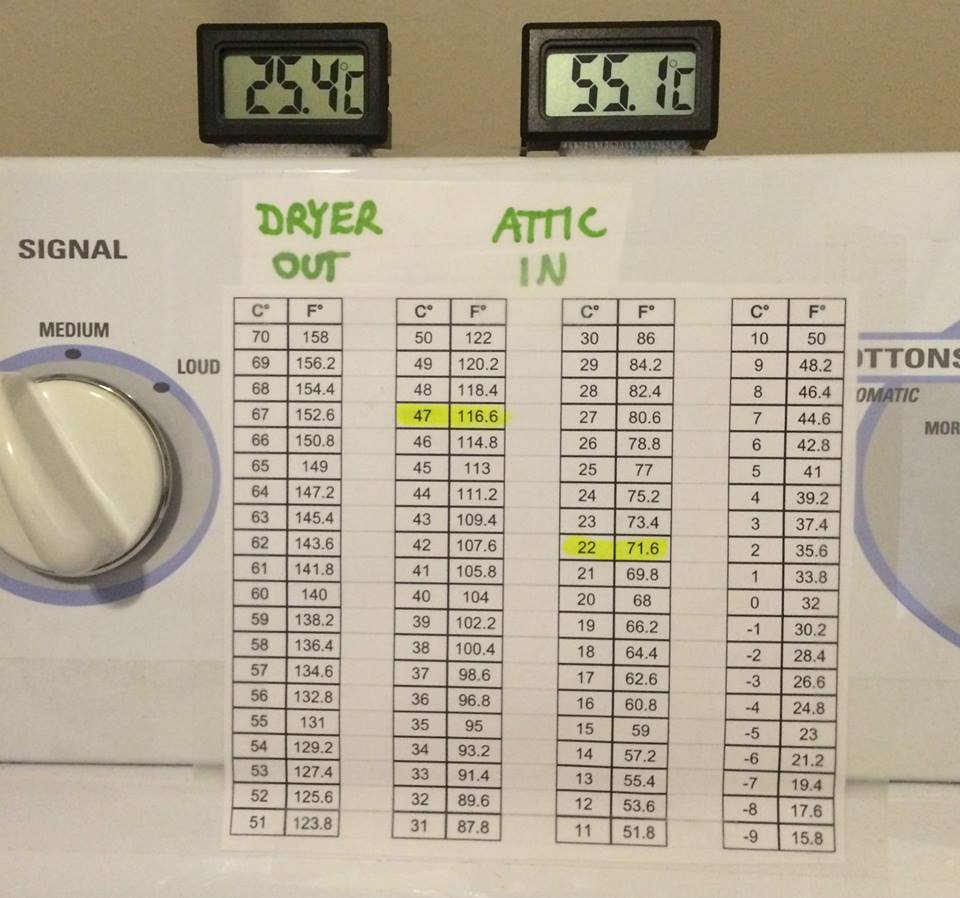

Temperature probe on the end of the attic air duct.

Monitoring attic air temperature allows you to know when it is better to draft air from the attic or when it is more efficient to draft air from inside the house, like normal.

As luck would have it, the interior wall behind the clothes dryer is extra thick. This made it easier to run the attic air intake duct.

A quick disconnect port was installed on the intake duct so the attic air can quickly and easily be bypassed for when the house air is warmer than the attic air.

Intake port on the laundry-room wall that pulls in hot attic air.

The attic air duct runs down the same wall where the dryer exhaust runs outside. Hot, dry, attic air in; moist, exhaust air out.

At upwards of 140°F, the aluminum intake duct radiates noticeable heat into the room. Insulating the duct keeps the laundry room at a comfortable room temperature.

Insulated attic air duct with a scrap of bubble wrap.

There is no difference in operating this "attic air drafting", electric clothes dryer and a normal clothes dryer. You just put clothes in, set the timer, start it up and walk away.

Electrically, the heating element still operates, just not as often or for as long.

Sometimes a clothes dryer works so well the clothes are dry, long before the timer finishes its cycle. Our dryer doesn't have a working humidity sensor, (those never work that well anyway). The temperature probe on the dryer exhaust serves as an indicator that the clothes might be dry.

The "Attic In" probe shows when it is more efficient to draft air directly from the house instead of the attic, (like in the winter time).

Temperature probes and temperature conversion chart.

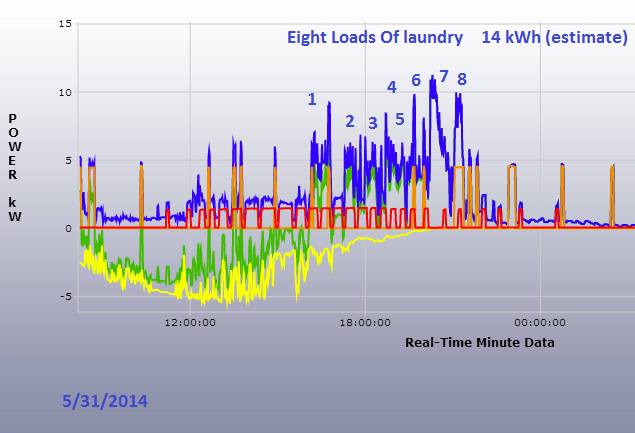

Energy savings is what is desired, only without anyone noticing. What used to require nearly 120 kWh per month now only takes 58 kWh. When the attic is 60 °C, the clothes dryer will pull in an extra 1.49 kWh of free heat from the hot attic air over the period of a 30 minute cycle.

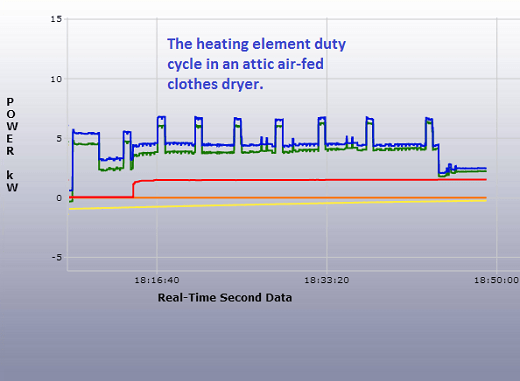

The duty cycle of the heating element.

Using TED (the energy detective) I am able to measure the heating element cycling on and off. Once things come up to temperature, the heating element actually cycles on and off quite a bit.

On this particular dryer setting (above), the heating element kicks on full blast until the clothes come up to temperature. Then it cycles from low-heat to high heat the rest of the time. While it may appear that the duty cycle is very low, the heating element is still drawing 2700 watts.

What's Running (Electric dryer) Power Consumption

Tumbler/Blower Motor 314 watts full / 312 watts empty

Heating Element (low) 2700 watts

Heating Element (high) 5100 watts

As the clothes get more dry, the heating element goes strait from "high" to "off". So as to better calculate duty cycle, the following measurements were taken under these conditions:

With the dryer drawing air from the attic, I timed a few heating element cycles. Then I pulled off the intake air vent from the wall port and let it draft from the house air. Then I timed the heating element cycles again.

Then I put it back to attic air. I repeated this exercise a couple more times.

While drafting from the house air (laundry-room was 76° F), the heating element had a duty cycle of 1:2.7 (on for ~30 seconds and off for ~80 seconds).

While drafting from the attic air (136° F), the heating element had a duty cycle of 1:6 (on for ~30 seconds and off for ~180 seconds).

When the attic is hot like this, the dryer is using less than ½ the energy it would otherwise.

Air Source Temperature Heating Element Duty Cycle

House Air 76 °F 1:2.7 (on for 30 off for 80)

Attic Air 136 °F 1:6 (on for 30 off for 180)

The only down-side I can see from doing this is it exposes the clothes dryer's blower motor to higher temperatures. Having experienced some very hot and muggy laundromats in the deep South, this is a common occurrence. I'm not too concerned.

What about using a Gas Dryer?

I would not recommend modifying a gas clothes dryer to draft hot attic air. Altering the draft of the combustion air could have very negative consequences. Natural gas has the uncanny ability of creating deadly carbon monoxide when burned improperly. This could KILL YOU and EVERYONE else in your household. Don't risk it!

In case your are interested, here is some energy usage data on our fancy gas dryer before we got rid of it and forever parted ways with natural gas.

What's Running (Gas Dryer) Power Consumption

Tumbler/Blower Motor 168 watts full/ 154 watts empty

Igniter 308 watts for 30 seconds each time gas cycles on/off

Heater 18,000 BTU = 5409 watts/hour

Using the utility natural gas meter on the side of the house, I measured 0.2 ft^3 of natural gas usage in 39 seconds, (0.9725 coefficient) which equates to about 5260 watts/hour. Pretty close to the 18,000 BTU rating.